Added Apr 22, 2024

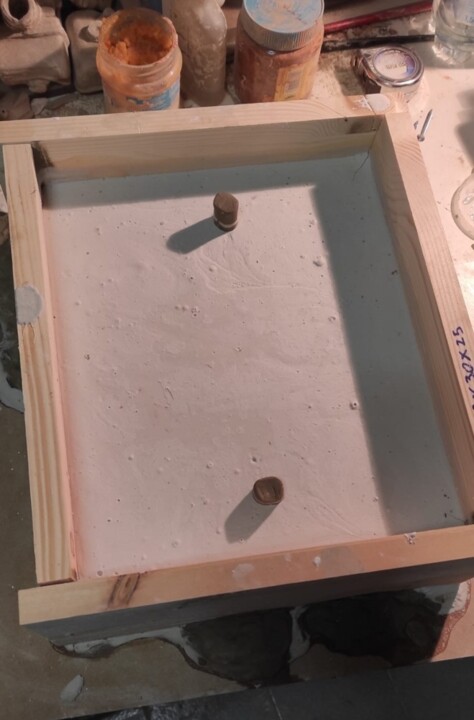

Preparation of the Gilera Arcore casing mold

I am of the opinion that even a mechanical piece has its charm.

This is the reason why I want to reproduce the side casing of a "Gilera Arcore", produced from 1972 to 75.

Initially the piece was completely solid, it was very heavy and a waste of material.

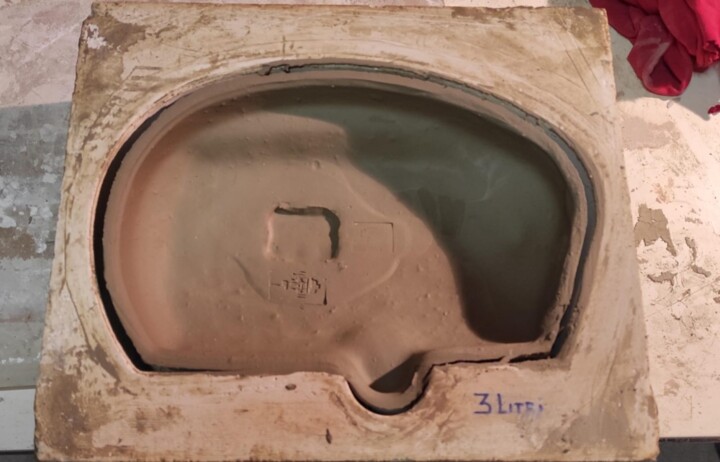

With a second test I did it with the casting system (slip) so that only the edges show a thickness, I like the result...

Once the slip casting slowly dries in the air and hardens, the piece detaches from the mold because the water contained in the slip is absorbed by the mold itself, creating a vacuum, after which you just need to turn the mold upside down and you're done.

By mistake I created a hole that I had to repair with another pour of liquid clay.

Finding the ideal thickness is not easy, the piece must be resistant at the same time as not coarse.

If you wish to leave a comment, your opinion or advice is all welcome

(learning by doing errors)

The piece looks good when it comes out of the mould, once dry the piece loses around 10% of its size and is slightly smaller. The original holes were made.

Personally I prefer to clean and smooth the ceramic once it is dry, with very fine sandpaper I can eliminate small imperfections.

Drying the ceramic is very important, the piece must dry slowly, it should not be placed directly in the sun, so it takes a few days and a lot of patience. On one crankcase I didn't take the central weight into account, and therefore as it dried the central part collapsed slightly.

The last stage is cooking at 1000 degrees centigrade.

I'm undecided whether to leave the raw piece in a ceramic colour, or to enamel it...